| Product name | Pall ring |

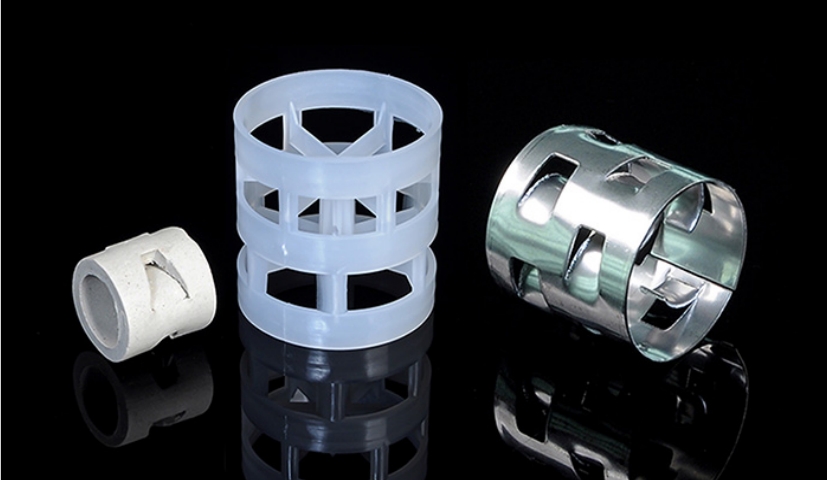

| Material | Metal, Plastic, Ceramic |

| Diameter | 16 / 25 / 38 / 50/ 76 /80 /89mm |

| Height | 16 / 25 / 38 / 50/ 76 /80 /89mm |

| Free simple | Sample is available |

| Packaging | Jumbo bag and pallet |

| Payment method | T/T,LC, Western Union, PayPal, Escrow and Money Gram |

Pall ring is an efficient packing widely used in packing towers in the chemical, petrochemical and environmental industries to enhance the gas-liquid or liquid-liquid mass transfer process. On the basis of the raschig ring, the Pall ring packing has opened many holes like Windows, so that the gas and liquid in the tower can pass freely from the hole, the gas and liquid distribution in the packing layer has been greatly improved, and the separation performance has been significantly improved. Due to its excellent performance, Pall ring is currently the most used random packing.

Material:

The materials of Ball rings are metal, plastic and ceramic. The metal materials include 304/316/316L stainless steel and other alloy materials; Plastic materials include PP,PE,PVC,PTFE;

Application:

- Rectification: In the rectification process, the pall ring as a filler can increase the contact area between the gas and liquid phase and promote the effective separation of the components in the mixture.

- Absorption and desorption: In the process of gas purification or recovery, such as waste gas treatment, carbon dioxide absorption in synthetic ammonia production, pall ring can accelerate the mass transfer process of absorbers and solutes in the gas.

- Washing: In the gas scrubber, it is used to remove dust, acid fog or other harmful substances in the gas to improve the cleanliness of the gas.

- Cooling and heating: Through direct contact between gas and liquid, the pall ring can be used for heat exchange of process fluids, such as water vapor cooling in cooling towers.

- Catalyst support: In some chemical reactors, pall ring can be used as a support material for fixed bed reactors, carrying catalyst particles to ensure good gas-liquid flow and reaction efficiency.

- Desulfurization and denitrification: In flue gas desulfurization (FGD) and selective catalytic reduction (SCR) denitrification systems, pall ring acts as a filler to participate in key chemical reaction processes to effectively remove sulfur oxides and nitrogen oxides from flue gas. Selecting the right rasping ring material and size is critical to improving efficiency, reducing costs and meeting specific operating conditions.

Features:

- Low resistance: The special design of pall ring reduces the resistance during the passage of gas and liquid, resulting in improved hydrodynamic performance.

- Large flux: Due to the reduced resistance, pall ring can allow more gas or liquid to pass through under the same conditions, that is, the processing capacity is improved.

- Large flexibility of operation: Pall ring can still maintain high efficiency in the case of large flow fluctuations.

- High separation efficiency: the structural improvement increases the gas-liquid contact area, thereby improving the mass transfer efficiency and making the separation process more efficient.

- Space saving: Pall ring can handle the same amount of processing as raschig ring with less volume, which can save space.

- Durability and adaptability: Pall ring can choose different materials according to the application requirements, such as ceramic, plastic or metal. The ceramic pall ring is resistant to acid and alkali and heat, the plastic pall ring is lightweight and not easily broken, and the metal Pall ring has excellent corrosion resistance and wear resistance, suitable for working in harsh environments.

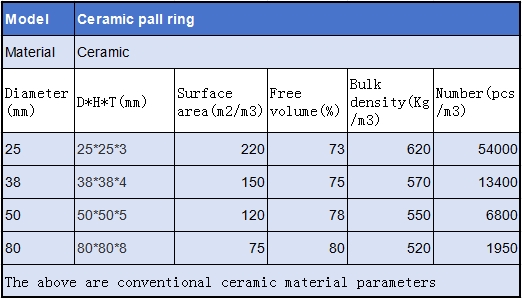

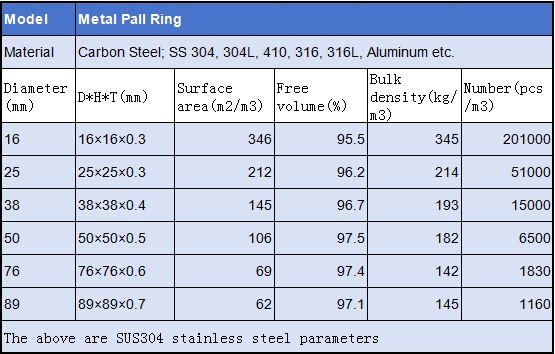

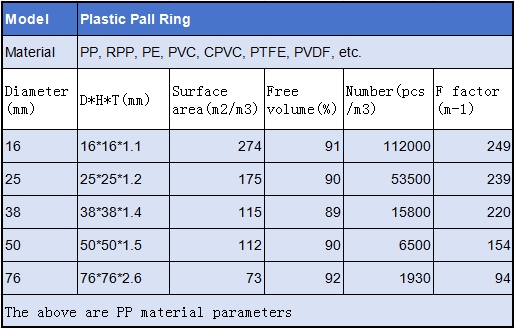

Specification:

Specification: φ16/25/38/50/76mm

Material: Carbon steel, stainless steel, Aluminum,alloy etc.

Packing: woven bag, ton bag

Specification: φ16/25/38/50/76mm

Material: PP/RPP/PVC/CPVC/PTFE

Packing: woven bag, ton bag

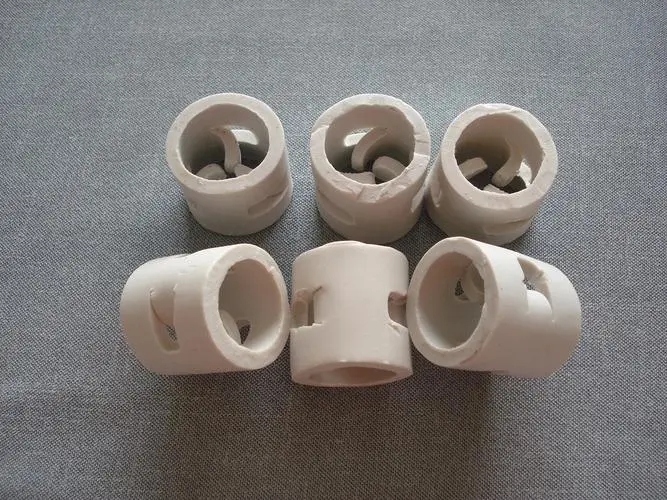

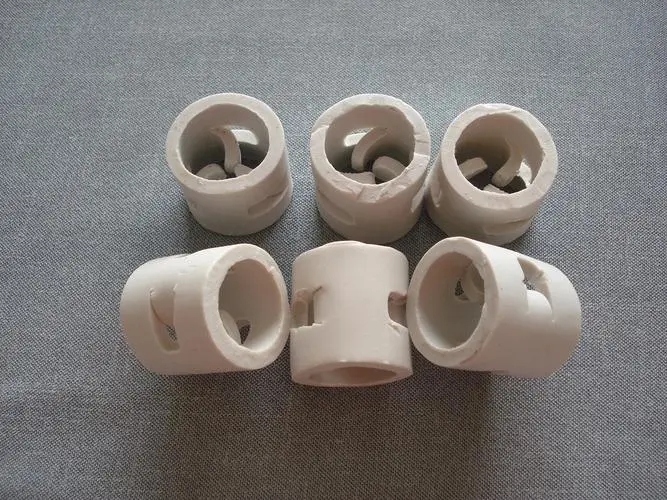

Specification: φ25/38/50/80mm

Material: Ceramic

Packing: woven bag, ton bag