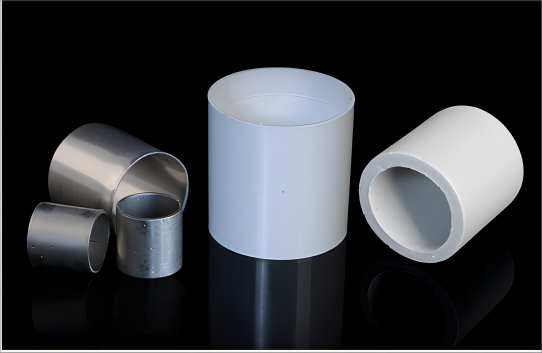

| Product name | Raschig ring |

| Material | Metal, Plastic, Ceramic, Carbon, Glass |

| Diameter | 16 / 25 / 38 / 50/ 76 /80 /89mm |

| Height | 16 / 25 / 38 / 50/ 76 /80 /89mm |

| Free simple | Sample is available |

| Packaging | Jumbo bag and pallet |

| Payment method | T/T,LC, Western Union, PayPal, Escrow and Money Gram |

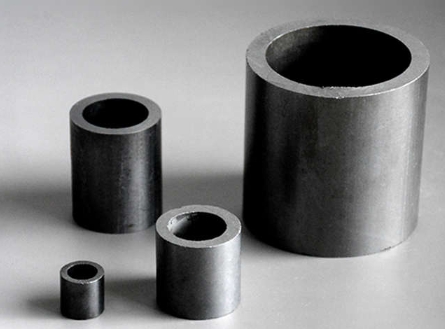

Raschig ring is a classic type of random packing, which is mainly used in packing towers in chemical and petrochemical industries. Mass and heat transfer processes are facilitated by enhancing the contact between gas and liquid or between liquid and liquid. It was invented by Fritz Raschig in 1914, and its shape is simple, with an outer diameter equal to the height of the circle. Raschig ring packing has the advantages of high porosity, large void and small resistance, so that the gas and liquid in the packing tower can pass freely, and the gas and liquid distribution in the packing layer is good. In particular, the inner surface of the raschig ring is easily wetted by liquid, no matter how it is placed, some of the liquid spilled onto the filler flows along the outer wall and some along the inner wall. In this way, the dispersion of the liquid increases, and the utilization rate of the inner surface of the packing is improved.

Raschig ring materials include the following:

- Ceramic: high temperature resistance, corrosion resistance, suitable for acid and alkali and other corrosive environment.

- Metal (such as 304/316/316L stainless steel, carbon steel) : high strength, suitable for high temperature and high pressure and mechanical wear occasions.

- Plastics (such as PP/PE/PTFE) : light weight, low cost, suitable for general chemical processes, especially for material economy requirements.

- Glass: transparent, easy to observe the internal fluid distribution, suitable for laboratory research or special requirements.

- Carbon/Graphite: high temperature resistance, good thermal conductivity, suitable for occasions requiring good heat conductivity.

Features:

- Simple structure: easy to manufacture and install.

- Diverse materials: It can be made of different materials such as ceramics, metals (such as stainless steel), plastics, graphite, glass, etc., to adapt to different working environments and chemical compatibility needs.

- Corrosion resistance: Especially ceramic raschig ring and plastic raschig ring have good acid and alkaline resistance, suitable for a variety of chemical media.

- Low price: Although the mass transfer performance of raschig ring is lower than that of other types of fillers, it is still used by many factories because of its simple structure, easy manufacturing and low price.

Applications:

- Chemical industry: In chemical production, raschig ring is used in various tower equipment, such as drying tower, absorption tower, cooling tower, regeneration tower, etc., to promote the mass transfer between gas and liquid or liquid for chemical reaction, absorption, desorption, washing and heat exchange processes.

- Metallurgical industry: In the metallurgical industry, raschig ring is used in gas purification and recovery systems to help remove harmful gases or recover valuable chemicals.

- Gas oxygen production: In the production of gas and oxygen, the raschig ring acts as a filler to improve the processing capacity and efficiency of the gas, while also participating in the purification process of the gas in some cases.

- Environmental protection: In wastewater treatment and air purification facilities, the raschig ring helps to remove pollutants from the water or harmful gases in the air, promoting the adsorption and decomposition of harmful substances by providing a large surface area.

- Energy industry: In thermal power plants and other energy conversion facilities, raschig ring is used for heat exchange and chemical reaction processes such as desulfurization and denitrification to reduce environmental pollution. Laboratory applications: In chemical laboratories, raschig rings are often used as basic experimental equipment for fixing reactants or carriers and conducting various chemical reaction experiments.

- Application of special materials: such as graphite raschig ring, because of its high temperature resistance and corrosion resistance, especially suitable for reaction devices in strong corrosive environments.

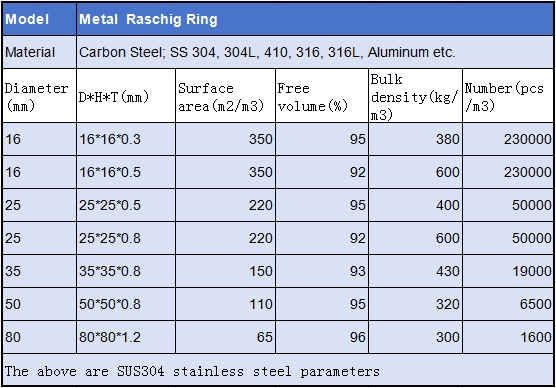

Specification: φ16/25/35/50/80mm

Material: Carbon steel, stainless steel, Aluminum,alloy etc.

Packing: woven bag, ton bag

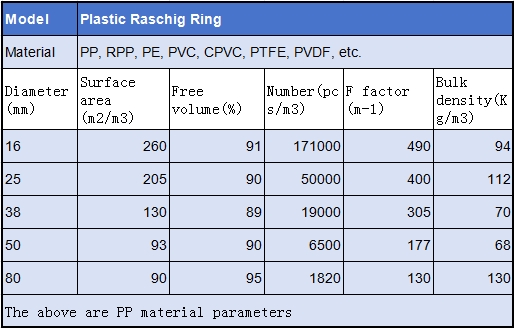

Specification: φ16/25/38/50/80mm

Material: PP/RPP/PVC/CPVC/PTFE

Packing: woven bag, ton bag

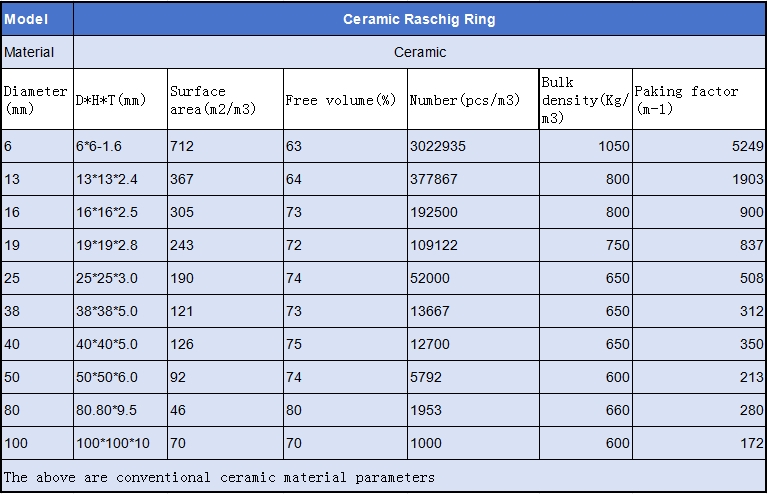

Specification: φ19/25/38/50/80mm

Material: Ceramic

Packing: woven bag, ton bag

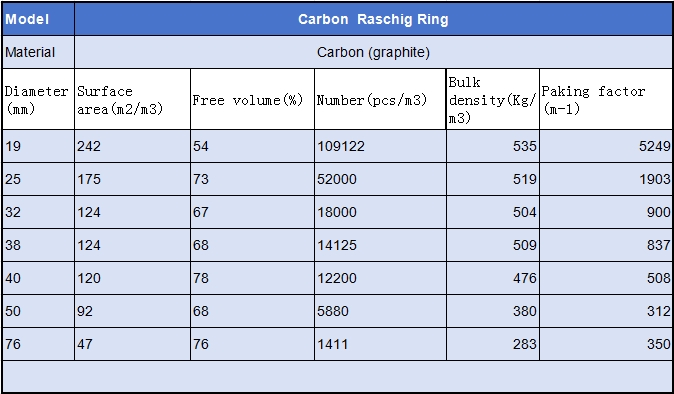

Specification: φ19/25/32/40/50/76mm

Material: Carbon(graphite)

Packing: woven bag, ton bag