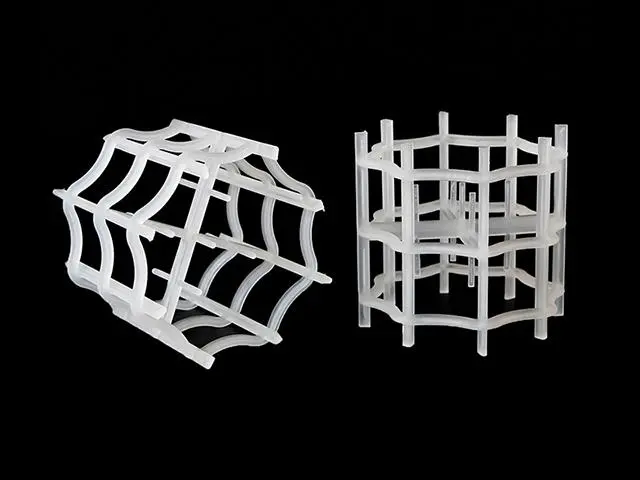

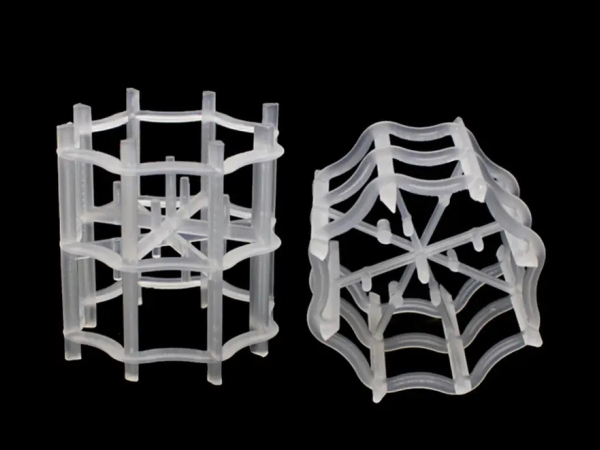

| Product name | Mella ring(VSP) |

| Material | Metal, Plastic, Ceramic |

| Diameter | 16 / 25 / 38 / 50/ 76 /80 /89mm |

| Height | 16 / 25 / 38 / 50/ 76 /80 /89mm |

| Free simple | |

| Packaging | |

| Payment method | |

Mella ring(VSP) is a special packing, its appearance is similar to the garland, with multiple inner arc and outer arc composed of ring structure. The Mella ring consists of a series of staggered arcs that are arranged alternately along the axis and partially folded inward radially to form an open structure. This design provides a large voidage and surface area, which facilitates uniform gas-liquid distribution and reduces the risk of internal clogging.

Material:

Mella ring can be made from a variety of materials, including stainless steel, carbon steel, aluminum alloy, and various plastics (such as PVC, PP, PE, PVDF, RPP, CPVC, etc.)

Application:

Mella ring is widely used in packing towers in petrochemical, fertilizer production, environmental protection, pharmaceutical and other industries, especially suitable for vacuum distillation, processing heat-sensitive, easy to decompose, easy to polymerize, easy to form carbon materials, as well as gas washing, purification and other processes. The design of the Mella ring makes it ideal for gas-liquid washing and separation processes to improve separation efficiency and product quality in chemical production.

Features:

Compared to other types of packing, such as the Pall ring, the Mella ring has higher flux, lower pressure drop, and better mass transfer efficiency. The use of Mailer ring can improve the processing capacity and efficiency of packing tower and reduce energy consumption. At the same time, the open structure of the Mella ring reduces adhesion and fouling between the fillers, facilitating cleaning and maintenance, and extending the service life of the equipment