| Product name | Intalox saddle |

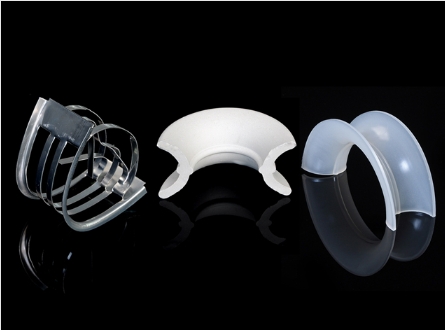

| Material | Metal, Plastic, Ceramic |

| Diameter | 25 / 38 / 50/ 76 /80mm |

| Height | 12.5 / 19 / 25/ 38 /40mm |

| Free simple | Sample is available |

| Packaging | Jumbo bag and pallet |

| Payment method | T/T,LC, Western Union, PayPal, Escrow and Money Gram |

Intalox saddle is a kind of random packing commonly found in packing towers in chemical, petroleum, environmental and other related industries. It is named for its shape between the ring and the saddle, and this unique design allows it to combine the advantages of the ring and the saddle. Intalox saddle is designed to improve gas-liquid contact in the tower, thereby increasing mass transfer efficiency and tower productivity.

Feature:

- Large flux: The special structure of the intalox saddle makes the resistance of gas and liquid through the packing layer less, so that it can withstand higher fluid flow and improve the processing capacity of the tower.

- Low pressure loss: Due to the hydrodynamic design of Intalox saddle, Low pressure loss compared to conventional packing, it can reduce equipment energy consumption

- High efficiency: Intalox saddle provides more surface contact area, which helps to improve the mass transfer efficiency of the gas-liquid two phases, making the separation process more effective.

- Strength and rigidity: Rectangular intalox saddles are usually made of high-strength materials, such as ceramic, metal or plastic, which guarantees the stability and durability of the packing during long-term use.

- Uniform distribution: the shape of the intalox saddle ring helps to evenly distribute the liquid in the packing layer, reduce the phenomenon of liquid ditch flow, and improve the efficiency of the packing layer.

Applications:

- Drying tower: Used to remove moisture from the gas.

- Absorber: Used for gas purification, such as removal of harmful components or recovery of valuable components.

- Cooling tower: Used for heat exchange, cooling gas or liquid.

- Scrubber: Used to remove solid particles or dissolved matter from gas.

- Regeneration tower: Used for catalyst regeneration or solvent regeneration process.

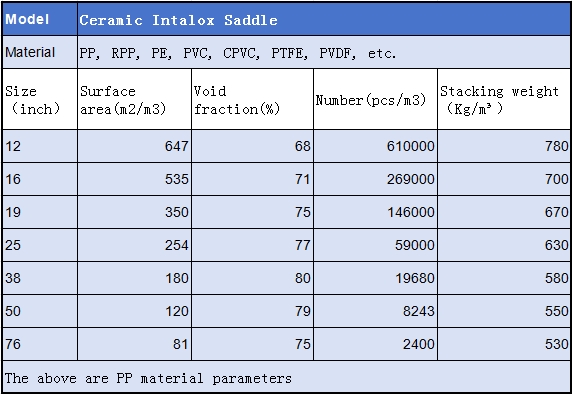

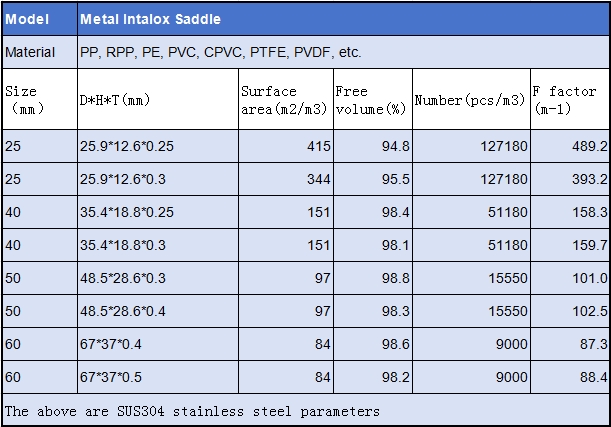

Specification

Specification: 25/35/48/67mm

Material: Carbon steel, stainless steel, Aluminum,alloy etc.

Packing: woven bag, ton bag

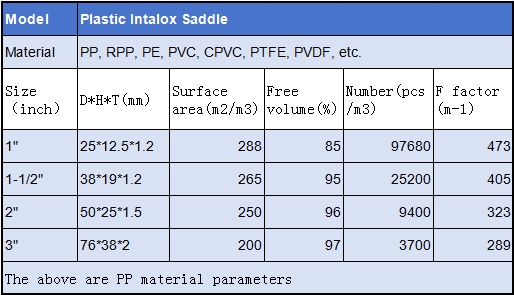

Specification: 25/38/50/76mm

Material: PP/RPP/PVC/CPVC/PTFE

Packing: woven bag, ton bag

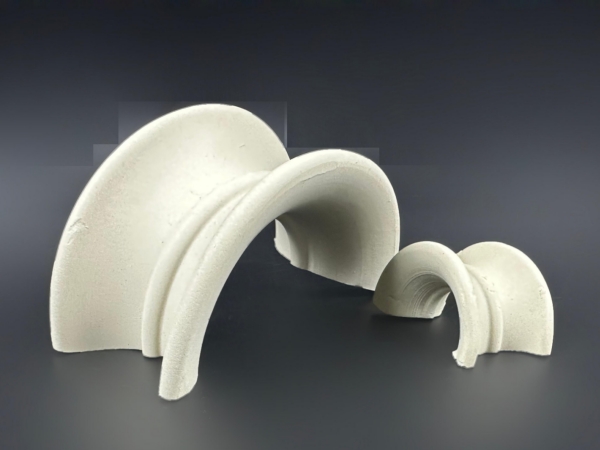

Specification: 16/25/38/50/76mm

Material: Ceramic

Packing: woven bag, ton bag